Tuesday, October 18, 2016

Tuesday, August 23, 2016

Friday, August 19, 2016

Monday, August 8, 2016

Alarms are for Safety

Loading...

Wednesday, July 27, 2016

Friday, July 22, 2016

Friday, July 15, 2016

Tuesday, July 5, 2016

Thursday, June 23, 2016

Wednesday, June 1, 2016

Thursday, May 5, 2016

Friday, January 15, 2016

What you need to know about ULPA filters?

What is an ULPA filter? Maybe this is what comes into your mind when you have read the title of this blog.

Well, ULPA (Ultra-Low Penetration Air) Filter is a dry extended media filter in a rigid frame, with a minimum particle-collection efficiency of 99.999%. Depending on the filter, the particle-collection efficiency can be measured at 0.3µm or at MPPS. (White, 2009)

It is different from HEPA (High Efficiency Particulate Air) filters in which HEPA filters are capable of removing 99.97% of particles with 0.3 µm diameter.

|

| Photo credits: http://www.globalspec.com/ |

Which is better?

Before answering that question, these are the things you should know about ULPA filters, in comparison with HEPA filters.

|

| Photo credits: http://labcrafts.com/ |

1. ULPA filters have a better filtration efficiency. ULPA filters have an efficiency of 99.999% compared to the efficiency of HEPA filters (99.99%).

1 vs 10. If 1 million spores are released on the work zone, only 1 spore will escape from ULPA filter while 10 spores will escape from HEPA filter. As you have noted above, ULPA filters exceeds HEPA filter efficiency. Therefore, it provides better operator and product protection.

2. ULPA filters provide an ISO Class 3 work zone.

What is ISO cleanroom classification?

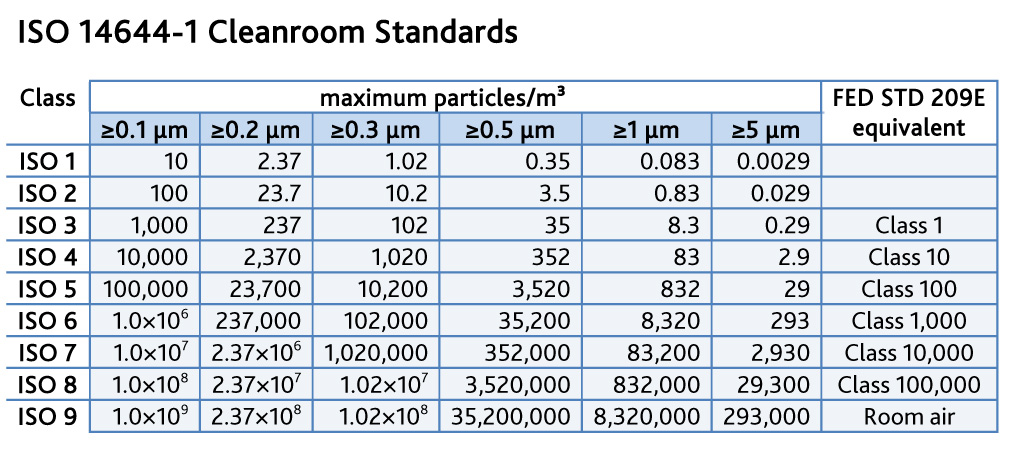

According to Terra Universal, ISO (International Standards Organization) cleanroom classifications are rated based on how much particulates of specific sizes exist per cubic meter. ISO Class 1 is the "cleanest" cleanroom, while ISO Class 9 is the "dirtiest" cleanroom. HEPA filters provide an ISO Class 5 work zone. Thus, ULPA filters offer substantially better product protection against contaminants.

|

| Photo credits: http://www.portafab.com/ |

|

| Photo credits: http://www.nafahq.org/ |

3. ULPA filter media has 5% higher pressure drop. As the pressure drop increases, the electrical power consumption increases. Moreover, as the pressure drop increases, filter life decreases. If HEPA and ULPA filters have the same filter media, HEPA filter has a longer filter life.

As a solution to this problem, ULPA filters can be designed to have larger filter media to have the same filter life as HEPA.

| Photo credits: http://animations.fg-a.com/ |

4. ULPA filter replacement cost is about the same, than HEPA filter.

On average, filter replacement cost is about $300 to 400.

So which is better?

At the same filter life and replacement cost, ULPA filters reduce the chance of operator infection and product contamination.

References:

FS209E and ISO Cleanroom Standards. Terra Universal. Available from http://www.terrauniversal.com/cleanrooms/iso-classification-cleanroom-standards.php

Pressure Drop Considerations in Air Filtration. National Air Filtration Association. Available from http://www.nafahq.org/pressure-drop-considerations-in-air-filtration/

White, E. 2009. HEPA and ULPA Filters. Journal of Validation Technology. [Online] p.54

Sunday, January 3, 2016

Beating post-holiday blues and ensure safety in the lab!

|

| Photo credits: http://thebalancingact.net.au/ |

Urg, can you believe it? The holiday season finally came to an end. Well, technically it ended on January 4. And what does that mean to us, lab people? It means we are back in the lab. Well, I feel you, guys. It is really hard to start working again after the holidays. Perhaps, many of us are suffering from post-holiday blues, or worse post-holiday syndrome. We can't deny it ~ after the holiday break, we may feel sad or unhappy. Don't be alarmed. It is a normal phenomenon. Hmm, I know it is hard but we should accept reality, right? Look into the bright side ~ you will be again culturing microbes. For sure, they have missed you.

|

| Photo credits: https://img1.etsystatic.com |

But wait! Before you streak your Petri dishes, check first if it is safe to work in your laboratory, especially in your biological safety cabinet.

So here are a few questions for you to answer.

1. Is my BSC certified?

It is a brand new year, so for biosafety cabinets that have not been certified yet, better contact your service provider and ask for re-certification of your BSC. BSC certification is needed to ensure that:

- its performance meets manufacturer's specifications

- the filter is not damaged, if physically relocated

- the cabinet's airflow and containment factors are within safe limits.

2. Do I wear the necessary PPEs?

|

| Photo credits: https://heavydutytruckpart.files.wordpress.com |

Sometimes, holiday season may cause us to forget all these laboratory protocols. Well, before you handle your specimens, make sure you are wearing necessary personal protective equipment. This is to minimize exposure to biohazards.

3. Have I allowed my BSC to purge prior to start of work?

To purge means to allow time for contaminated air to be removed from the cabinet environment. Yes, despite being unused during the holidays, the air inside your BSC should be purged. Better safe than sorry, ayt? Leave the blower on for at least 5 minutes before using the cabinet.

Better check if the alarm is working or not, before you start your work. This is to ensure that your BSC is fully operational, including the alarms. Some BSCs have sophisticated alarm system, including sash alarms. Try to move the sash to an improper position. You will expect that the sash alarm will sound. Make sure the alarm is not in mute though. If the alarm still does not sound, then there's something wrong with your BSC. Consult your service engineer for assistance.

| Photo credits: http://a.files.bbci.co.uk/ |

5. Have I surface-decontaminated my BSC work zone?

Same with purge cycles, your BSC work zone should be decontaminated prior to start of work even if it is unused during the holiday break. Materials to be placed inside the BSC should also be surface-decontaminated. Do not forget to surface decontaminate all items within the BSC and remove from the cabinet when work is completed.

6. Am I using a Bunsen burner inside the BSC?

Oops, do not forget that a Bunsen burner should not be used inside the BSC since it can cause airflow disturbance and can endanger you. Your samples will also be at risk of cross contamination. When absolutely necessary, ON/OFF switching type, or electric burners can be used.

I bet you are ready to work after you've answered the questions above.

So beat the post-holiday blues and ensure safety in the lab!

Happy culturing!

Subscribe to:

Posts (Atom)